This is an ideal machine for medium to larger projects such as bridge refurbishment work where mobility and high production rates are important.

This machine offers a continuous blast time of approx 55 minutes.

Fabricated from heavy gauge steel this blast pot is of the highest quality available.

Key Features

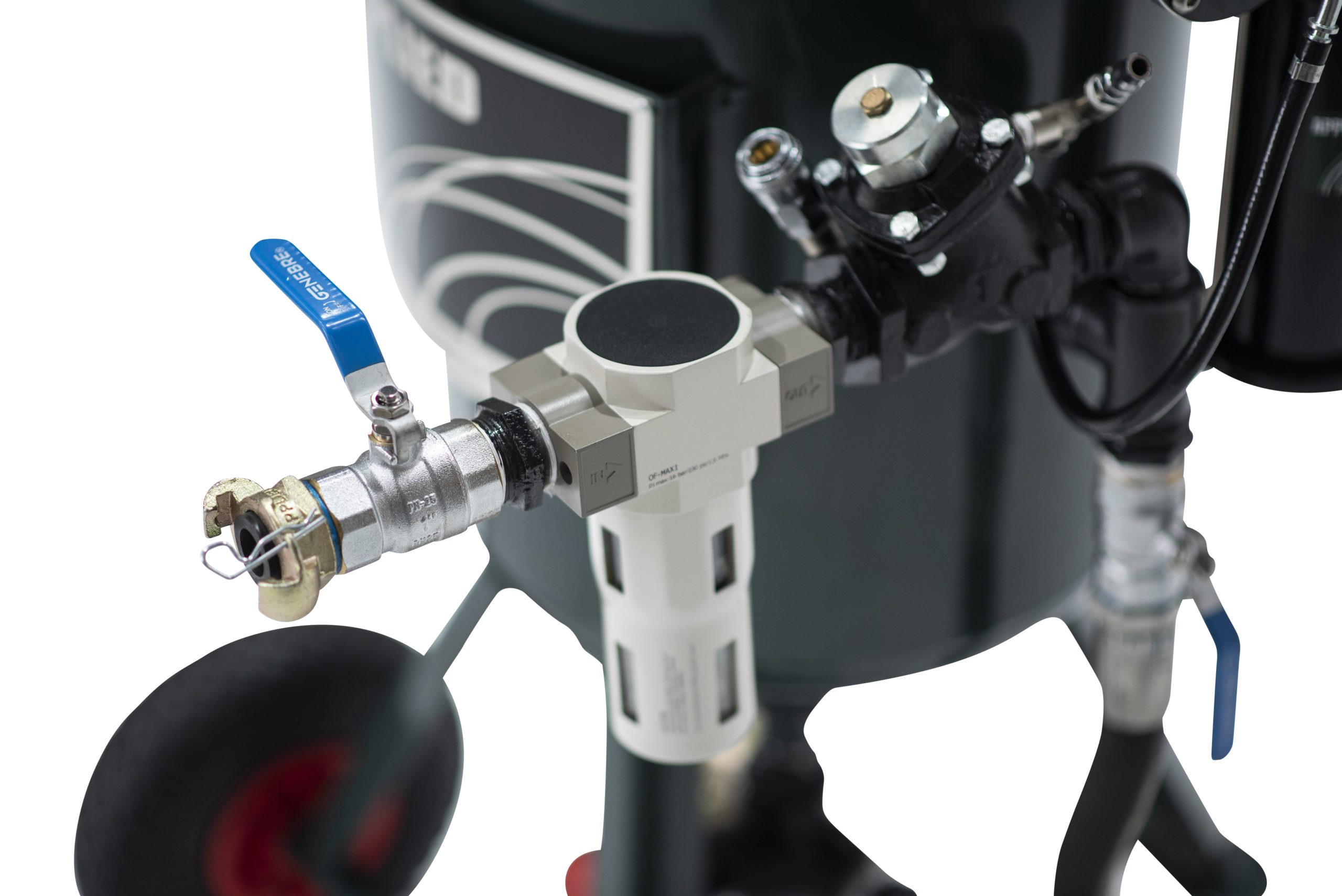

• Main air isolation valve for additional safety

• Concave top for rapid filling of pot which is sealed automatically

by heavy duty pop-up valve

• Conical bottom ensures all media flows to metering valve

• Inspection hole – Allowing easy access for inspection and maintenance

• Micro abrasive control valve

• Moisture/Water Separator – Assists in removing the water/moisture

from the incoming compressed air supply to the blast pot, thus

helping to ensure that the abrasive does not become damp

• Quick claw couplings fitted to ensure quick set-up

• Remotely Controlled Valve for quick activation and deactivation

of the machine

• Heavy duty puncture-proof wheels for increased mobility

• CE Approved

Specification

All Applied abrasive blasters are equipped with all necessary fittings, connections etc.

By delivery, one complete blasting machine package will be mounted on a wooden pallet.

Model: Applied 140

Media Capacity: 140 Litres

Tank Diameter: 520mm

Height: 1280mm

Blast time: Approx 55 Minutes

Piping: 1 ¼”

Supplied With:

THIS MACHINE IS SUPPLIED COMPLETE AND READY TO USE WITH

• 10 Metres of Heavy Duty Blast Hose

• 11 Metres of Twinline Control Hose with AirFlo Handle

• Boron Carbide Nozzle

• 10 Metres of air supply hose, complete with quick claw couplings, to ensure quick set-up

• 12 Month Warranty